Enigma Caravan

Alustain was registered in 1987 and since inception, under the guidance of its owner, Brett Morrison, the company has been supplying metalwork for the domestic and commercial building industry. With a can-do attitude and a focus on detailing and quality, Alustain has become a reputable metalwork business that is sought after by many well-known designers and architects.

The idea of the expanding style caravan came from a convoy road trip to Port Stephen’s back in 2016. After setting up our vans and tents we heard that a storm with 20 to 30 knot winds was heading our way, hence followed a mad panic to pack up anything that would be damaged in the storm. Awnings and tents were first thing along with all the apparatus set up under them. Permanent caravans, on the other hand with rigid awnings held strong through the storm and survived without damage.

This is the reason we decided to build a van that has all the space and benefits of a permanent caravan but is transportable.

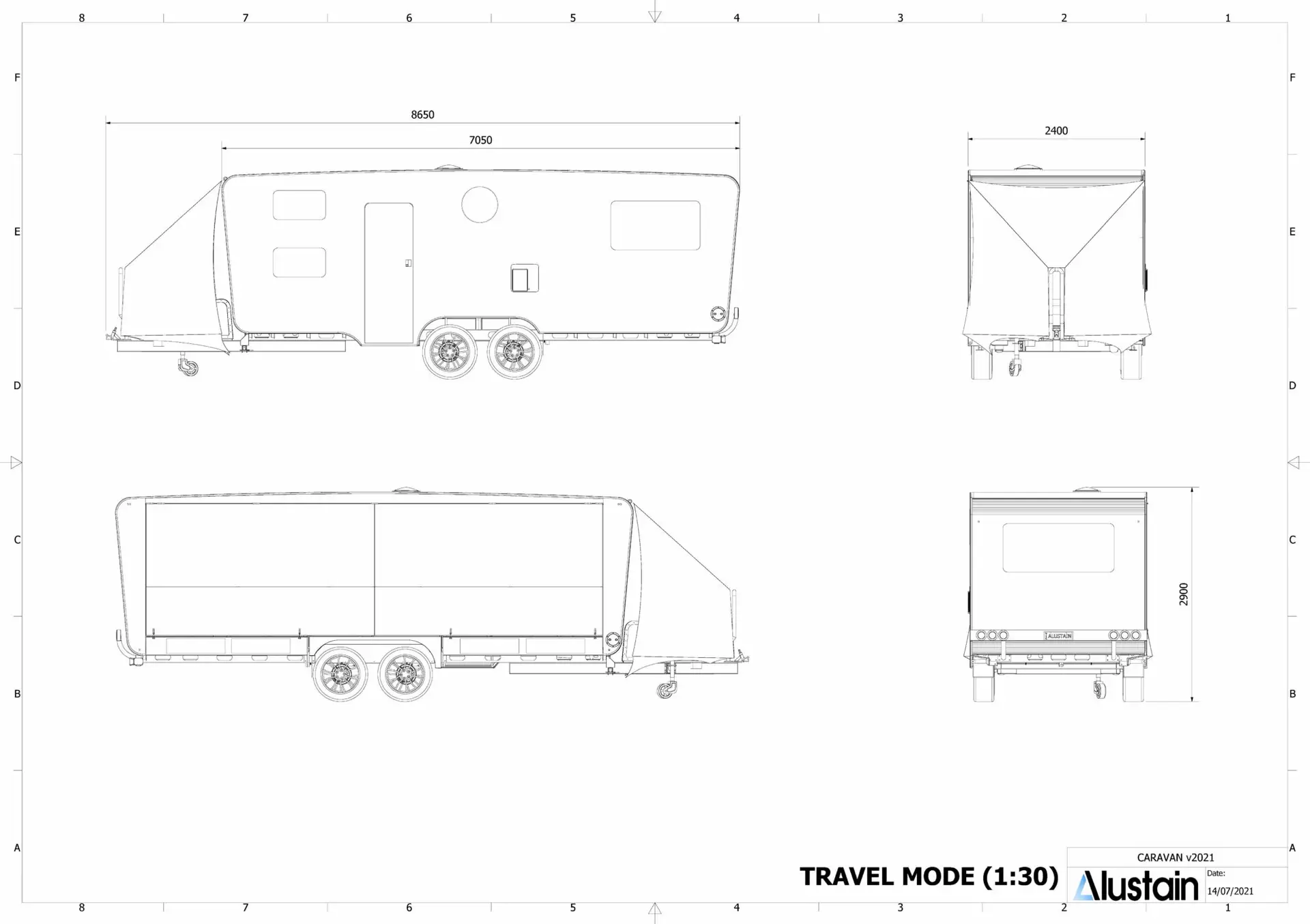

Once the opening mechanism was sorted, the rest was easy. With the help of our CAD guys the construction of every part was designed to be as simple as possible using folding, fixing and material thickness best suited to each application for a sturdy construction.

We have all heard about the “sticks and staples” vans on the market, and the horror stories that follow. The last thing we want to build is a van that will not last.

Click on the titles to find more details

3mm mild steel laser cut, folded with flared holes for strength and access to services all hot dip galvanised.

Both mounted within the chassis, lift and retrieve access via 12-volt winch.

There are 3 underfloor storage boxes with access hatches inside the van.

The first box houses the hydraulic and water pump, with excess space for personal storage.

The second box houses Batteries and the inverter, with excess space for personal storage.

The third box is entirely for storage.

5 mm toughened low E grey tint glass.

custom made aluminium frames powder coated to match interior.

1.6mm clear anodised aluminium sheeting.

1.2mm powder coated aluminium sheeting.

12 volt LED throughout.

Diesel 5 kw and split Fujitsu 2.5 kw

Annexe awning rooftop is hoisted using two electric winches mounted on the inner side of the chassis rails. A second stage awning roof is opened by hand and secured in place with four S/S latches, this occurs in the mid open position of the primary roof.

The Main floor is lowered using 12-volt hydraulic rams. A second stage extension is then opened with two more hydraulic rams to complete the full width floor. The floor structure is stabilised and levelled using telescopic legs which are wound down with an impact driver or a hand tool.

Once the main floor is level and the ceiling is fully extended slightly above level, the walls at each end can swing open and lock into position with the floor. The outer wall support tubes can be fitted, and the ceiling can be lowered and locked into position.

Once the hard walls, ceiling and floor are locked, the canvas walls can be zipped to the support tubes completing the opening of the awning deck.

Throughout the design process our focus has always been on quality design and refinement. We hope you enjoy the unique feeling of space that we have created.

Alustain Installations Pty Ltd was formed in 1987, in Melbourne Australia. After completing a sheet metal apprenticeship in stainless fabrication, owner Brett Morrison started from a humble back yard environment in the outer suburbs of Melbourne.

© 2019 All rights reserved

Site Developed by KRUMS Pty Ltd